ECO 솔루션

가스연료 저장 및 공급설비

PURIGAS

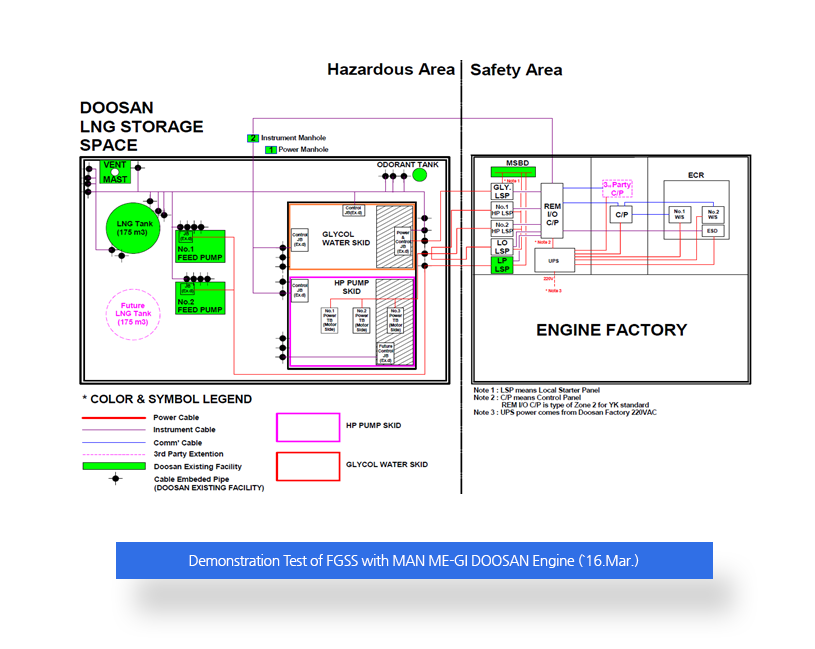

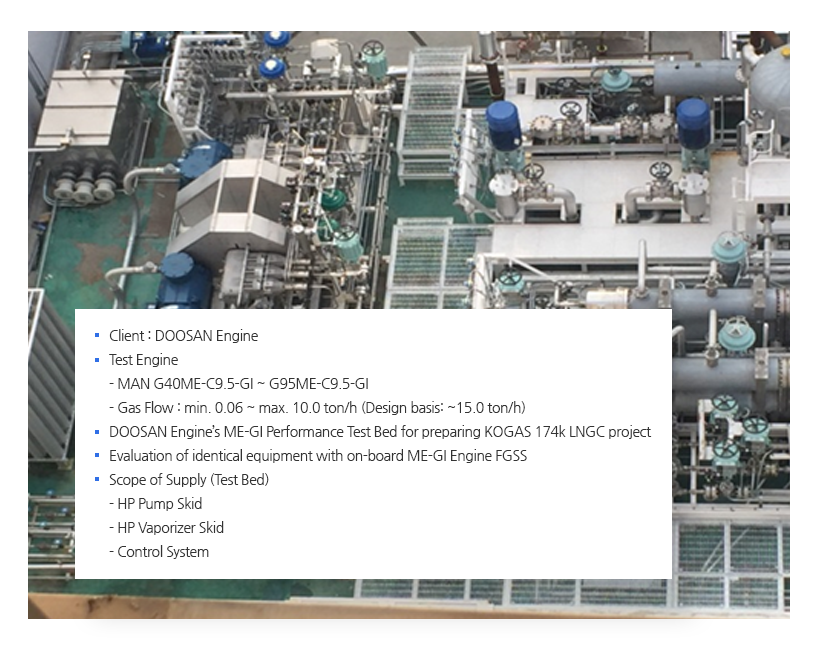

PURIGAS™은 연료 가스 저장 및 공급 시스템(FGSS) 용 패키지 솔루션 모델명으로 Pure & Intelligent GAS 저장 및 공급 시스템을 의미합니다

FGSS는 IMO의 SOx, NOx 및 GHG 배출 제한에 가장 효과적인 솔루션이지만 초기투자비용(CAPEX)와 설치 공간은 FGSS 솔루션적용에 큰 장애물입니다.

이를 해결하기 위해 에스엔시스社(S&SYS)와 삼성중공업(SHI)社의 LNG 관련 장비에 대한 축적된 기술과 엔지니어링 역량으로 PURIGAS™가 개발되었습니다 축적된 노하우로 PURIGAS™는 고객에게 가장 경제적이고 안정적인 패키지 시스템을 제공할 것 입니다.

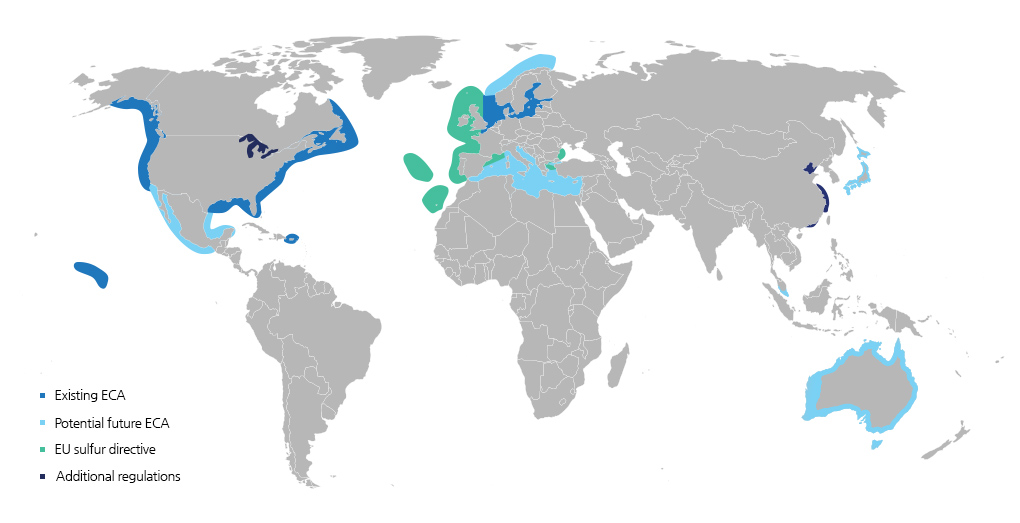

Reinforcement of regulations for the conservation of the marine atmosphere by IMO, under the UN

1997 MARPOL Protocol : SECAs ( ECAs)

| Baltic Sea | Adopted 1997/ into force 2005 |

|---|---|

| North Sea | Adopted 2005/ into force 2006 |

| North American coasts | Adopted 2010 / Into force 2012 |

| US Caribbean Area | Adopted 2011 /Into force 2011 |

| Outside an ECA | Inside an ECA |

|---|---|

| 4.5%prior to 1.Jan. 2012 | 1.5%prior to 1.July. 2010 |

| 3.5%on & after 1.Jan. 2012 | 1.0%on & after 1.Jul. 2010 |

| 0.5%on & after 1.Jan. 2020 | 0.1%on & after 1.Jan. 2015 |

Existing ECA zones and possible future ECAs

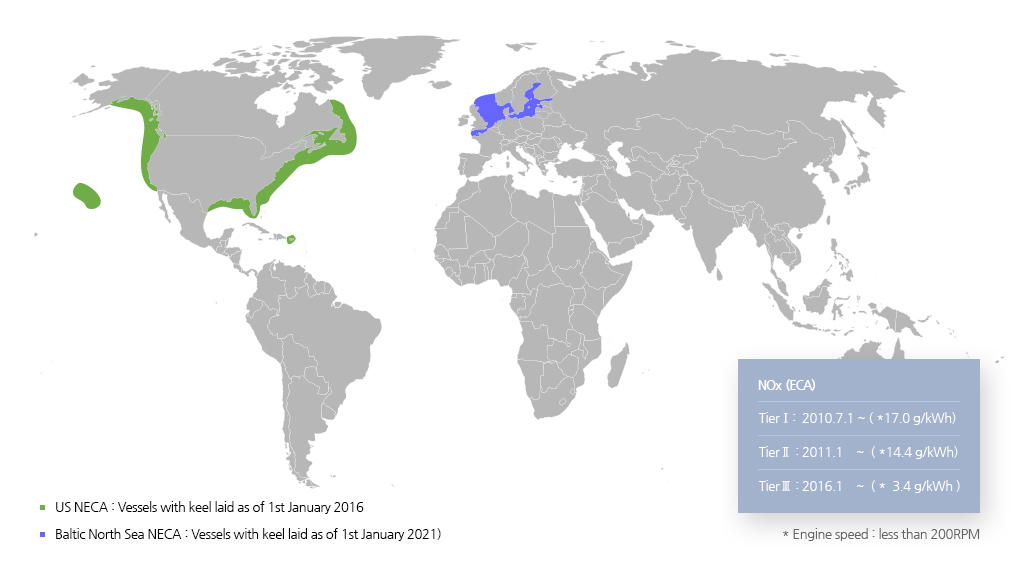

NOx Emission Control Areas (NECA)

Initial IMO strategy on Reduction of GHG emissions from ships

| Level of ambition | Timeline |

|---|---|

|

Carbon intensity of ships to decline

|

Short-term measures: 2018–2023

|

|

Carbon intensity of shipping to decline

GHG emission from shipping to decline

|

Mid-term measures: 2023–2030

Long-term measures: > 2050

|

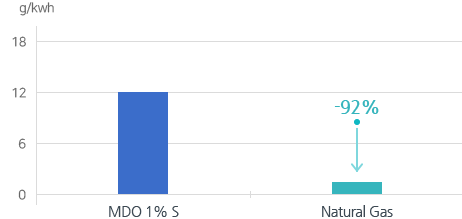

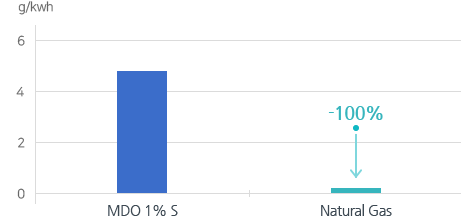

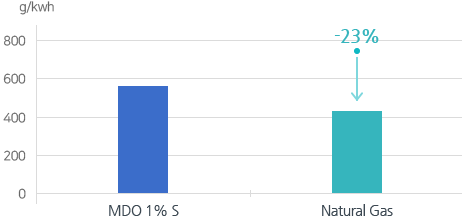

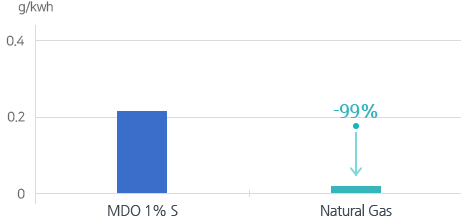

By using Natural Gas Instead of MDO, CO2 is reduced about 23% and SOx, NOx and PM are reduced more than 92%.

* Source: Marintek Report from Rolls-Royce DF Engine

-

NOx

-

SOx

-

CO2

-

Particulates

-

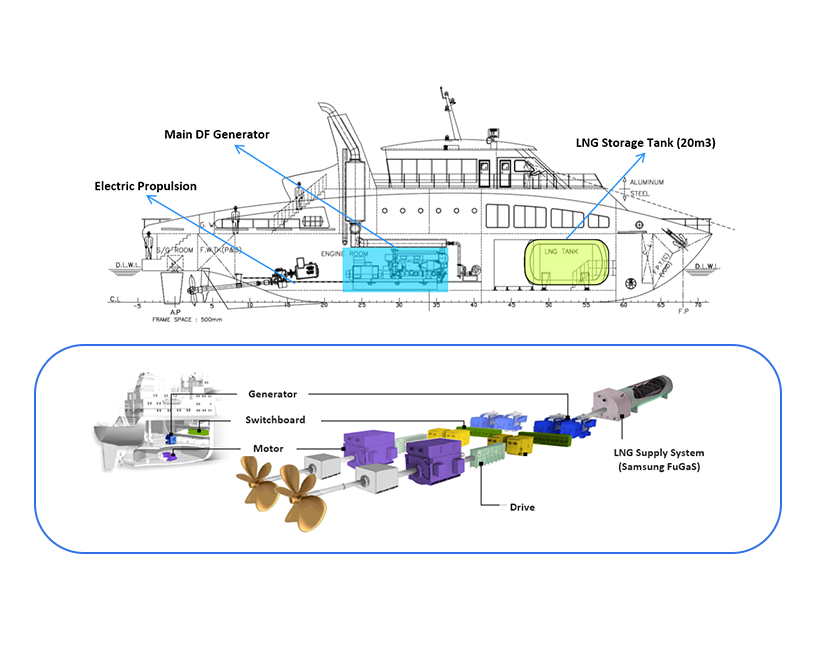

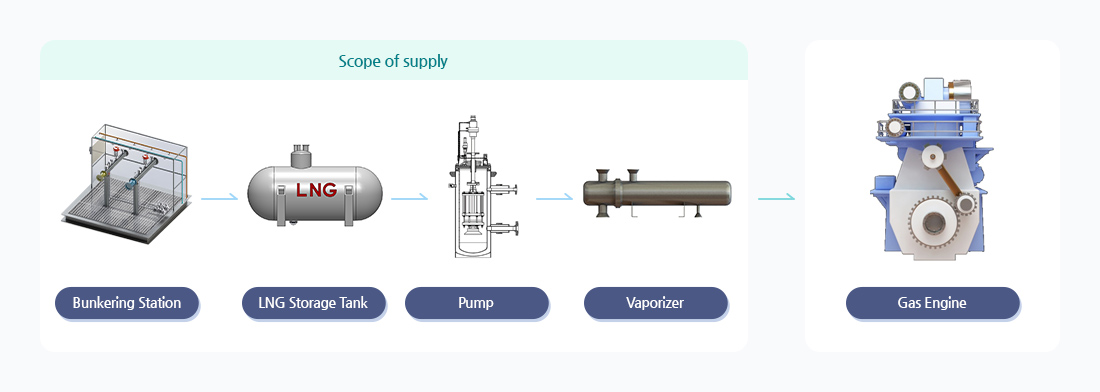

FGSS 엔지니어링 및 FGSS 장비에 대한 패키지 공급

- FGSS 엔지니어링 및 FGSS 장비 토탈 공급 서비스

- S&SYS의 자체 제어 시스템 20년 노하우를 바탕으로 한 효율적, 안정적 제어 프로그램 제공 -

다양한 선박에 대한 검증된 엔지니어링 기술 및 운전 경험

- 삼성중공업과의 다양한 FGSS 프로젝트의 설계 및 공급 경험을 바탕으로 한 검증된 엔지니어링 기술력

- Drying, N2 충전, Cooldown, 벙커링, 가스 시운전 등 다양한 운전 경험 -

다양한 선종의 FGSS 설치 및 시운전을 위한 엔지니어링 데이터

HAZID, HAZOP / FMEA / Cause & Effect chart / FAT 절차서 / SAT 절차서 / 가스 시험 절차서

FDS (Functional Design Specification) / 탱크 보존 절차서 / 운전 및 유지 보수 매뉴얼 / 이중 파이프 도면 등 -

고성능의 FGSS 제어 시스템

- LNGC IAS에 공급되는 고 성능의 안정적 하드웨어 적용

- 자동화 시스템에 대한 자가 진단 기능 제공

- 실시간 모니터링 및 Logic 시뮬레이션이 가능한 특화된 Logic 설계 프로그램 툴 제공

- 20년 노하우를 바탕으로 개발된 손쉬운 유지 보수 및 원격 유지보수 기능

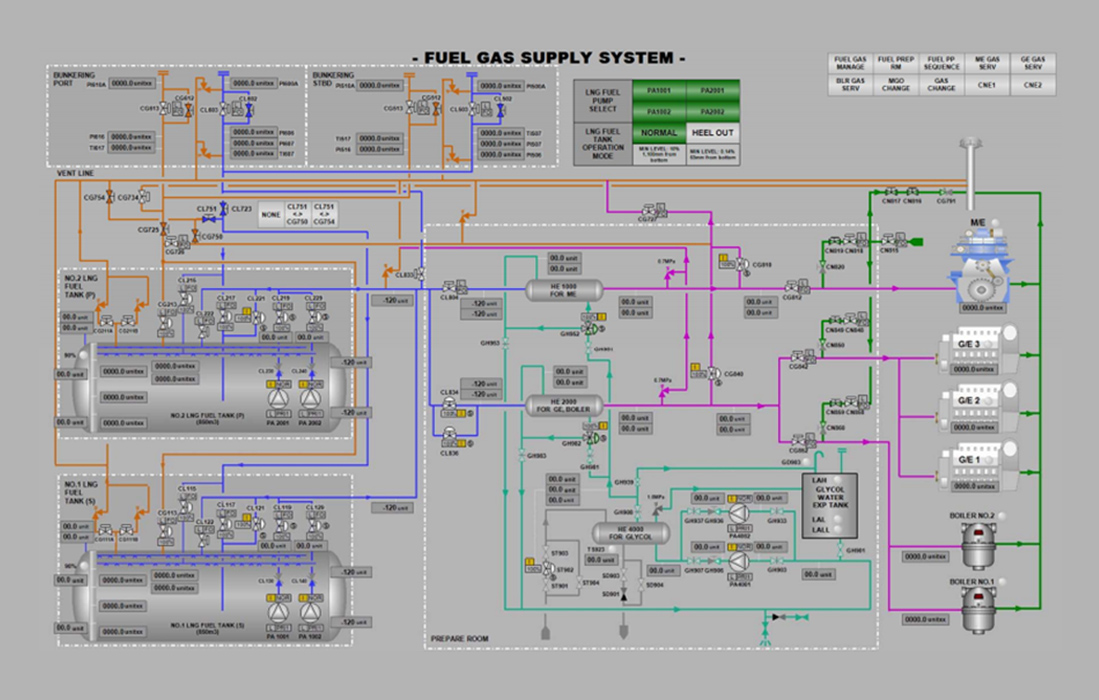

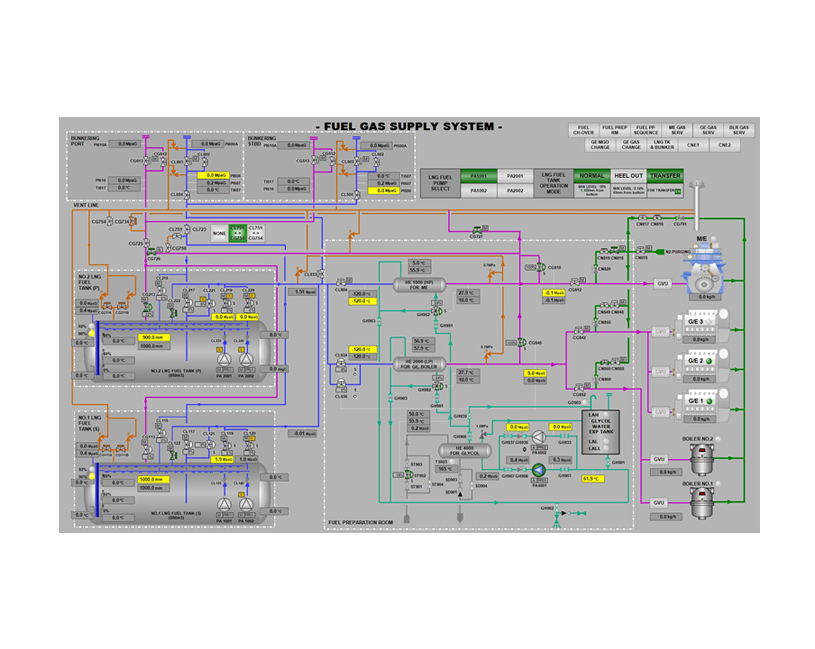

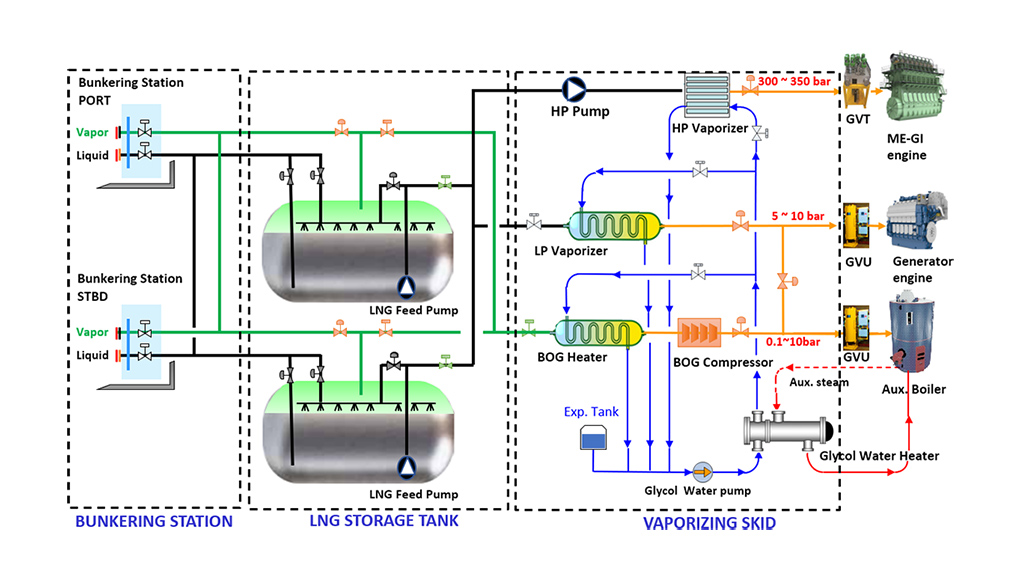

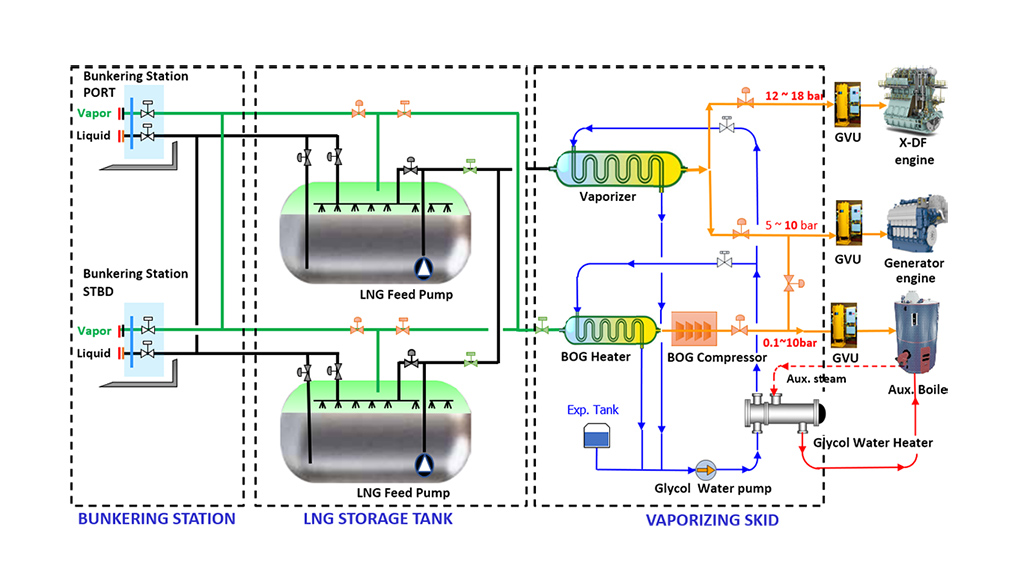

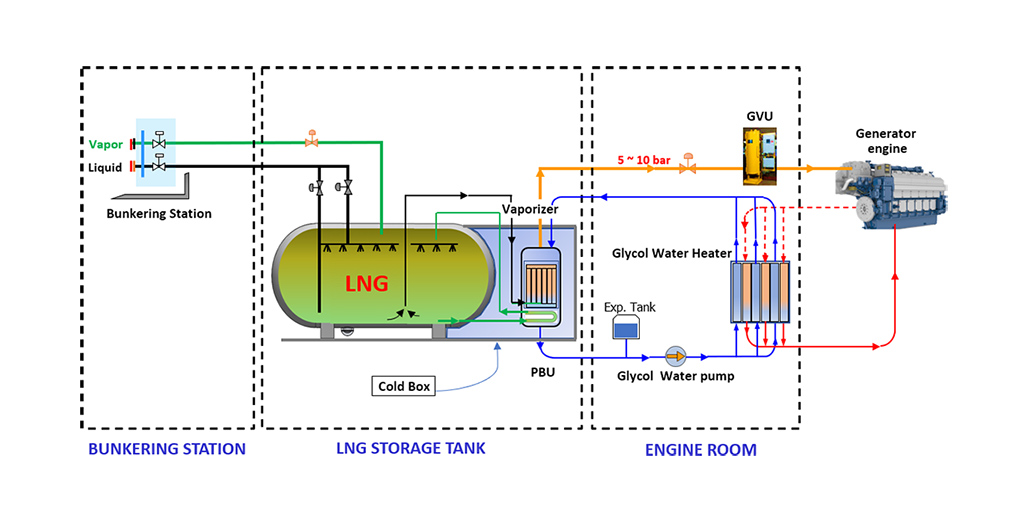

Flow Diagram

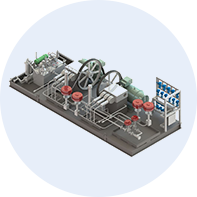

Major Equipment

-

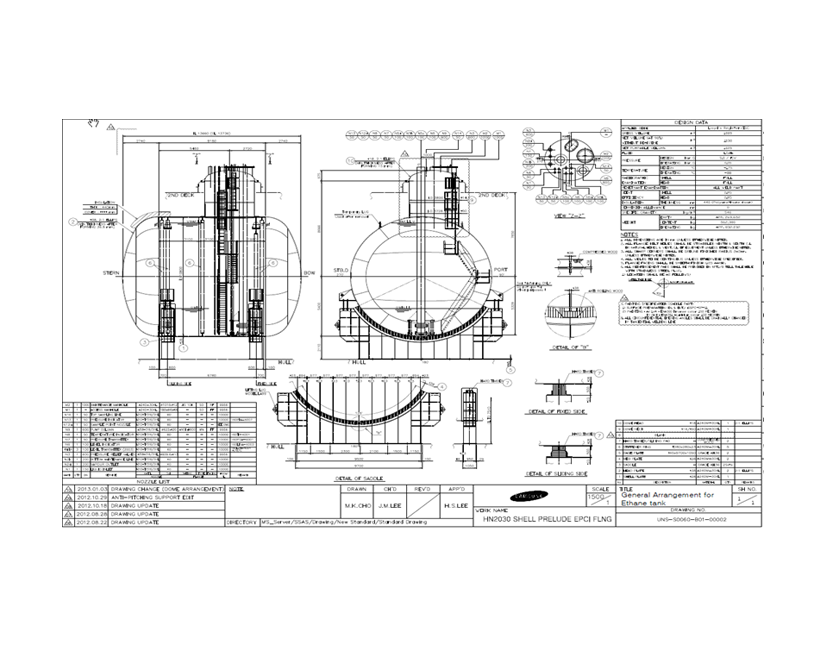

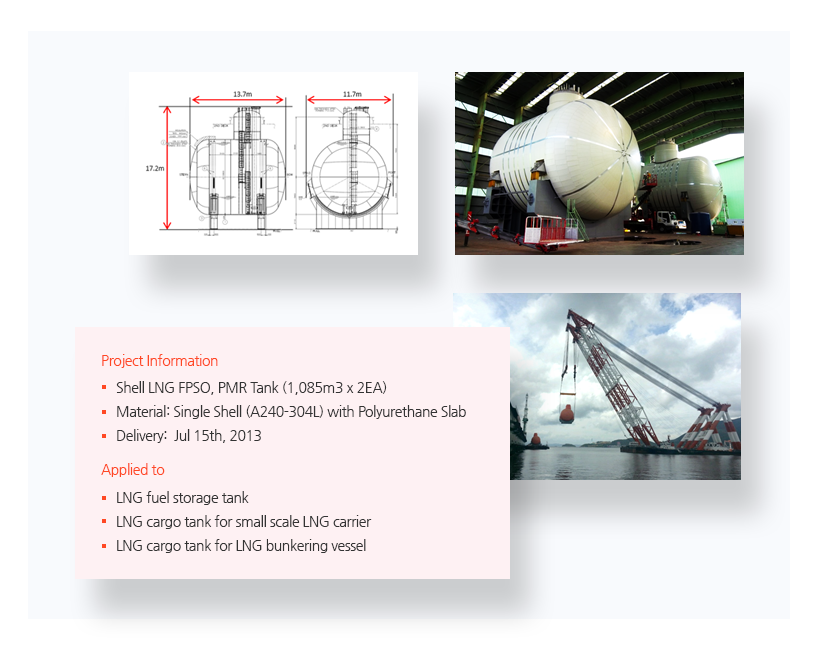

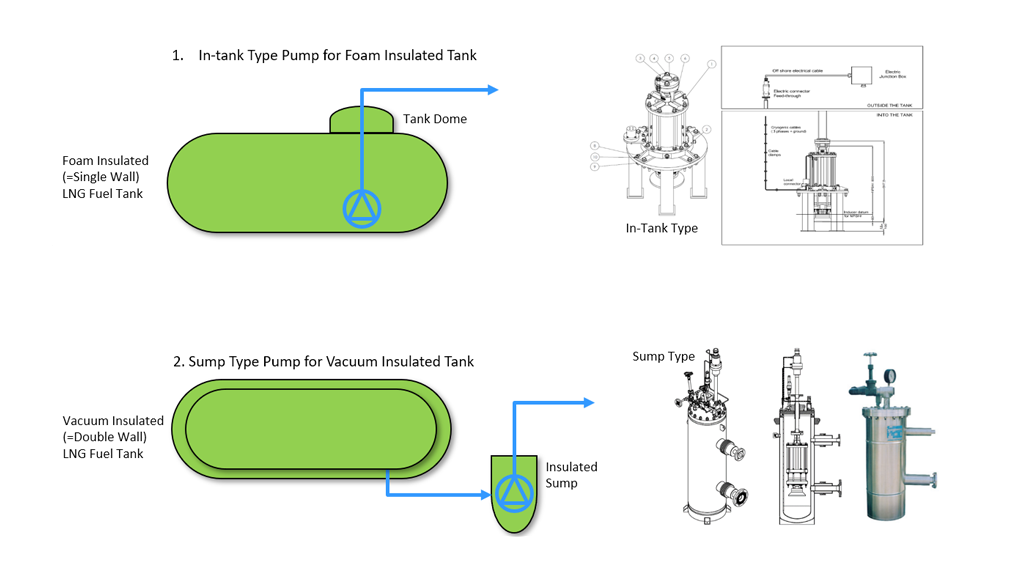

LNG Storage tank

-

Bunkering Station

-

Control & Monitoring system

-

H.P. Pump Skid

-

Vaporizer Skid

-

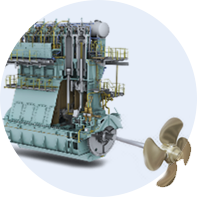

Engine

- 1. Quantity: 2 sets ( Port & Starboard shipside)

- 2. Liquid Line: 4 ~ 8” Pipe

Vapor Line: 4 ~ 6” Pipe

- 3. Dimension ( In accordance with SGMF guidance )

- Distance of manifold flanges inboard from ship’s side. : 1,100mm

- Horizontal distance between flange centers : 1,250 mm

- Vertical distance between flange center & working platform : * mm

( * depend on ship’s specification )

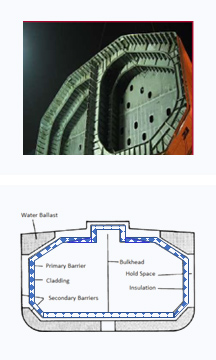

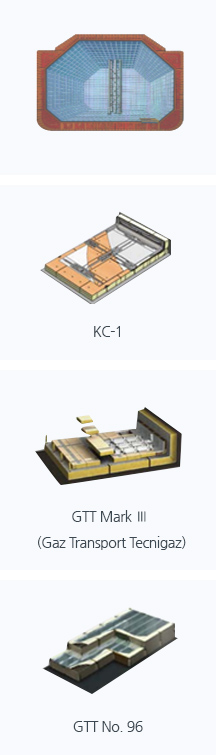

| IMO Classification of LNG Carriers( IGC Code) | |||

|---|---|---|---|

| Independent Tanks (separated from hull structure) | Integrated Tanks (part of hull structure) | ||

| Type A | Type B | Type C | Membrane Tank |

|

* Simple Design * Pο ≤ 0.7 bar * Full secondary barrier |

* Flat Design * Pο ≤ 0.7 bar * Partial secondary barrier |

* Simple Design * Pο ≥ 2 bar * No secondary barrier |

* Simple Design * Pο ≤ 0.7 bar * Full secondary barrier |

|

|

|

|

-

Double shell with Vacuum

-

ISO container (20ft, 40ft)

-

Single shell with PU

-

Bi-lobe Tank

-

Tri-lobe Tank

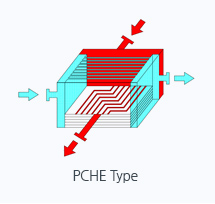

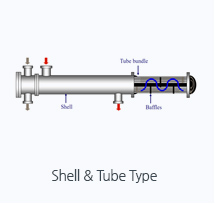

| High Pressure Vaporizer | Low Pressure Vaporizer | ||

|---|---|---|---|

|

|

|

|